article

What is Edge AI?

Artificial Intelligence (AI) has rapidly emerged as a transformative technology capturing the imagination of individuals and businesses alike. While AI is making significant inroads in our personal lives through virtual assistants and recommendation engines, Edge AI is proving to be the true game-changer for industrial equipment manufacturers and their customers.

Industry analysts recognize this shift—Gartner predicts that “By 2026, at least 50% of edge computing deployments will involve machine learning, compared to 5% in 2022,” highlighting the dramatic acceleration of intelligence moving to the network edge.1

1 Gartner(TM) Hype Cycle for Edge Computing, 2024

Definition of Edge AI

Edge AI—running AI algorithms directly on industrial equipment and field devices rather than in remote data centers—has evolved from an experimental concept to a critical capability driving the next generation of smart machinery. Unlike traditional cloud-based AI that requires constant connectivity and introduces latency, Edge AI brings intelligence directly to where data originates and where actions must be taken.

What is Edge AI and why does it matter?

At its core, Edge AI involves deploying machine learning models and analytics capabilities directly on or near equipment—on industrial controllers, smart cameras, sensors, and gateways at the “edge” of the network. This fundamental shift in where intelligence resides creates significant advantages for machinery that must operate reliably, respond instantly, and protect sensitive operational data.

For equipment manufacturers, Edge AI represents an opportunity to embed intelligence directly into their products, enabling machines to:

- Monitor their own condition and predict maintenance needs

- Detect quality issues in real-time during production

- Process sensitive data locally without transmission risks

- Optimize performance based on changing operational conditions

- Operate autonomously without constant connectivity

The industrial Edge AI advantage

For equipment manufacturers facing intensifying competition and pressure to deliver more value, Edge AI provides a path to differentiation through intelligence. Smart equipment that can optimize its own operation, predict failures before they occur, and adapt to changing conditions delivers measurable advantages that customers increasingly expect:

- Reduced downtime through predictive rather than scheduled maintenance

- Higher quality through real-time detection and correction of process deviations

- Lower operating costs through continuous optimization

- Extended equipment lifespans through adaptive operation

These capabilities transition industrial machinery from static assets that depreciate over time to intelligent systems that continuously adapt and improve—a fundamental shift in how equipment creates value.

Why Edge AI matters now for equipment manufacturers

For equipment manufacturers, Edge AI addresses critical operational and security challenges that cloud-only approaches cannot effectively solve.

Bandwidth and cost optimization

Modern industrial equipment can generate terabytes of sensor data daily. Transmitting all this raw data to the cloud is both prohibitively expensive and unnecessary. By processing data locally and sending only relevant insights, anomalies, or compressed features to cloud systems, Edge AI dramatically reduces connectivity costs while still enabling fleet-wide analytics and remote monitoring capabilities.

Energy efficiency advantages

For equipment operating in power-constrained environments or running on battery power, Edge AI delivers twofold energy benefits: reducing power consumption by minimizing data transmission, which is energy-intensive compared to local processing, resulting in extended operational time for battery-powered industrial equipment.

Privacy and security advantages of local processing

Industrial customers increasingly resist sending proprietary production data, process parameters, and intellectual property outside their facilities. Edge AI allows equipment to deliver advanced capabilities without exposing sensitive data, addressing a significant barrier to adoption. Machine vision systems can detect defects without transmitting images, equipment can optimize for efficiency without revealing process details, and predictive maintenance can function without exposing operational patterns that might reveal production volumes or methods.

Learn more about securing your IoT data

Operational reliability in disconnected environments

Industrial equipment often operates in challenging environments—remote locations, mobile applications, underground facilities, or areas with electromagnetic interference that impacts connectivity. Edge AI ensures that intelligent functions continue operating regardless of network conditions, maintaining safety, quality, and productivity even when cloud connections are unavailable or unreliable.

The unique challenges of Edge AI implementation

While Edge AI offers compelling advantages, equipment manufacturers face significant challenges when deploying AI capabilities at the edge that differ substantially from cloud-based implementations. Successful Edge AI implementation requires more than just technical expertise in machine learning; it also demands sophisticated orchestration capabilities designed for the unique constraints of industrial edge environments, often referred to as MLOps (Machine Learning Operations). Equipment manufacturers need edge orchestration platforms that can bridge the gap between powerful AI capabilities and the practical realities of deploying intelligence to diverse, distributed, and demanding industrial applications.

Managing model deployment across diverse hardware

Unlike cloud environments with standardized infrastructure, edge devices in industrial settings vary widely in processing capabilities, memory constraints, and supported software frameworks. Equipment manufacturers must navigate this heterogeneity when deploying models across different product lines, generations, and customer environments. Industrial MLOps platforms must provide hardware-aware deployment pipelines that can automatically optimize and package models for specific target devices while maintaining consistent behavior.

Monitoring distributed model performance

Understanding how AI models perform in the field is essential for continuous improvement, but visibility becomes challenging when models run on distributed edge devices. Equipment manufacturers need MLOps tooling to monitor inference quality, resource utilization, and drift detection across their deployed fleet without overwhelming network connections or compromising data privacy. Effective orchestration must include telemetry collection that respects bandwidth constraints while providing actionable insights.

Lifecycle management at scale

As AI models improve through continuous learning, distributing updated models to edge devices becomes a critical operational challenge. Industrial equipment may be deployed in restricted environments with limited connectivity windows, strict change management processes, and varying software compatibility. Managing this update process across hundreds or thousands of deployed machines—often operating in production-critical environments where downtime is costly—requires robust MLOps capabilities.

Security access and control

Deploying AI capabilities to edge devices introduces unique security challenges compared to cloud implementations. Models may contain valuable intellectual property that requires protection, while edge devices often operate in physically accessible environments with varying security controls. Equipment manufacturers must implement robust mechanisms for model encryption, secure updates, tamper detection, and access management that work reliably even in environments they don’t directly control.

The Edge AI ecosystem for industrial equipment

For equipment manufacturers, the optimal approach typically involves distributing intelligence across edge devices and cloud platforms to maximize both immediate responsiveness and long-term learning. When designing intelligent equipment, manufacturers should consider:

- Available computing resources at the edge

- Total cost of ownership including connectivity

- Requirements for cross-machine learning

- Data sensitivity and IP protection needs

- Customer environment connectivity limitations

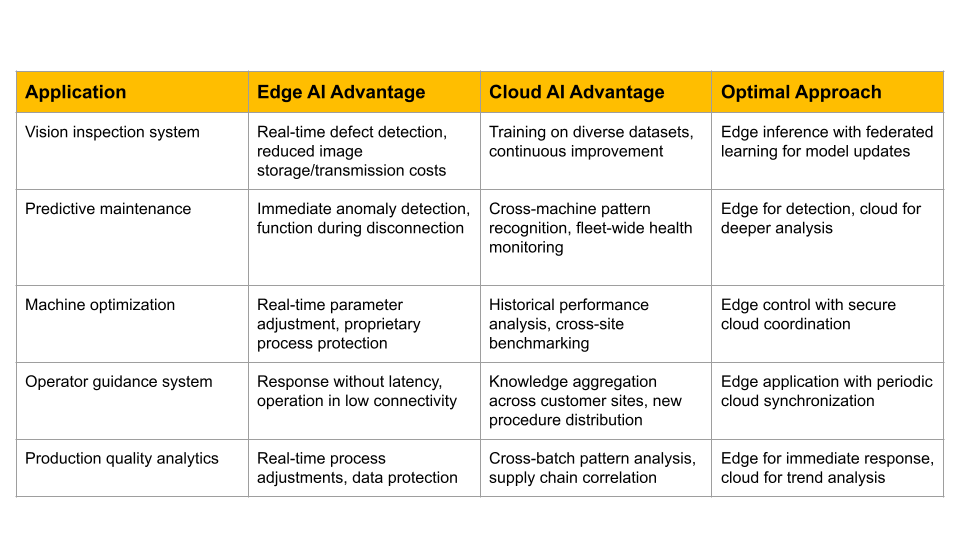

Benefits of Edge AI vs. Cloud AI

Hybrid approaches that leverage both paradigms

The convergence of edge and cloud computing can lead to a hybrid approach that leverages the strengths of both paradigms. Leading equipment manufacturers implement “edge-first, cloud-enhanced” architectures where edge systems handle real-time operation, immediate decisions, and data pre-processing, while cloud platforms manage model training, cross-system optimization, and fleet-wide intelligence. This tiered approach delivers immediate value while creating a foundation for continuous improvement based on aggregated learning.

- Edge Devices: For equipment manufacturers, edge hardware options include purpose-built industrial controllers with integrated AI acceleration, smart cameras and machine vision systems with onboard processing, ruggedized edge gateways designed for harsh environments, and embedded AI accelerators that can be integrated into existing equipment.

- Cloud Coordination: While Edge AI emphasizes local processing, industrial cloud platforms remain essential for training machine learning models on data aggregated across equipment fleets, orchestrating model updates to distributed machines while respecting production schedules, and providing development environments for Edge AI applications.

- Data Flow: Industrial Edge AI transforms raw machine data into operational intelligence through a sequential process of data collection, signal processing, model inference, decision logic, action, and continuous learning. Edge AI systems rely on efficient data movement between layers to balance latency, security, and computational efficiency.

Emerging Edge AI Technologies for Equipment Manufacturers

Several specialized Edge AI technologies are particularly relevant for industrial equipment:

Vision AI at the edge

- Machine vision systems with integrated AI can perform tasks previously impossible with traditional computer vision:

- Identifying subtle quality defects even with product variation

- Adapting to changing lighting conditions and material presentations

- Classifying multiple failure modes rather than simple pass/fail inspection

- Learning new defect patterns without extensive reprogramming

Leading implementations integrate cameras directly with edge processing to minimize latency and bandwidth while delivering insights rather than just images.

Small Language Models (SLMs) at the edge

While large language models (LLMs) require substantial computational resources, optimized Small Language Models are bringing sophisticated natural language capabilities to edge devices:

- Enabling context-aware maintenance guidance through local conversational interfaces

- Supporting natural language commands for equipment control and configuration

- Providing real-time documentation and troubleshooting assistance even in disconnected environments

- Translating between specialized industrial terminology and plain language for operator accessibility

These edge-deployed language models are orders of magnitude smaller than their cloud counterparts but offer focused capabilities tailored to specific industrial domains.

Federated Learning for protected improvement

Federated learning represents a breakthrough for equipment manufacturers concerned with data privacy:

- Edge devices train on local data, sharing only model updates rather than raw information

- Equipment improves based on fleet-wide experience without exposing customer operations

- Models gain diversity from exposure to different operating environments and conditions

- Implementation provides continuous improvement while respecting data sovereignty

This approach addresses a critical barrier to AI adoption in industries with sensitive intellectual property.

Moving Forward with Edge AI

As Edge AI continues to mature, equipment manufacturers have unprecedented opportunities to differentiate their products through embedded intelligence. By distributing AI capabilities throughout the machine lifecycle—from design and production to operation and maintenance—equipment makers can deliver equipment that continuously adapts, optimizes, and creates value throughout its operational life.

The next step for manufacturers interested in exploring Edge AI opportunities is to assess their current equipment offerings and identify high-impact applications where intelligence at the edge could deliver meaningful customer value. Starting with focused use cases that address specific customer pain points—like quality control, predictive maintenance, or energy optimization—provides the foundation for broader intelligent equipment strategies.

Want to learn more about how AIoT is transforming industry?

Learn more about how organizations like yours are using AIoT to improve operations, speed decision-making, and introduce new business models to their customers.