Remote Monitoring

Stop problems before they stop your equipment

Remote monitoring of connected assets allows operations, field service, and product development teams to incorporate live data into condition monitoring, service management, and product evolution processes.

Gain the data you need to easily update software and firmware, track asset performance, develop new product features faster, and deliver the capabilities that matter most to your customers.

With Cumulocity, you can connect and monitor your devices in minutes, not weeks or months.

We’ve been able to learn so much about how our compressors actually run on-site, and we’re using that information to make improvements that directly benefit our customers. With energy efficiency as a top priority for most companies right now, we are able to use our machine-learning platform to identify opportunities that deliver real value.

Jair Junior

Automation Projects Manager

Mayekawa Mycom

You need the full picture to operate effectively

Limited visibility into machine health

Many manufacturers lack real-time insights into machine conditions, relying on manual checks or outdated data. Sensors and IIoT connectivity provide continuous, data-driven visibility into performance, allowing for early detection of anomalies, allowing for faster root-cause analysis and better decision-making.Inconsistent product quality

Machine wear, vibration, or temperature fluctuations can subtly affect product tolerances or surface finish, increasing scrap and rework. Connected equipment sends real-time information on conditions and potential failures, as well as enabling IoT remote management of firmware and software updates to improve operating quality and enhance security.Production bottlenecks and scheduling issues

Unpredictable equipment performance makes it hard to plan production or coordinate maintenance across multiple lines. Real-time asset data supports more accurate scheduling, so maintenance can be aligned with production cycles and use of resources is optimized.Make more informed product development decisions

With a clearer understanding of how equipment is used in the field and the drivers of maintenance issues and performance breakdowns, your product development efforts can be better focused on the most impactful areas for your customers.Build customer loyalty

Unpredictable equipment performance makes it hard to plan production or coordinate maintenance across multiple lines. Real-time asset data supports more accurate scheduling, so maintenance can be aligned with production cycles and use of resources is optimized.The numbers tell the story

$9 billion

size of the market for condition-based monitoring solutions by 2035, with the largest markets in Germany, the United States, China, and Japan.

Source: Future Market Insights

76%

of industrial equipment is now networked.

Source: IoT Signals

70%

of companies do not have complete awareness of when assets are due for maintenance.

Source: Baker Hughes

Cumulocity provides insight into equipment operations

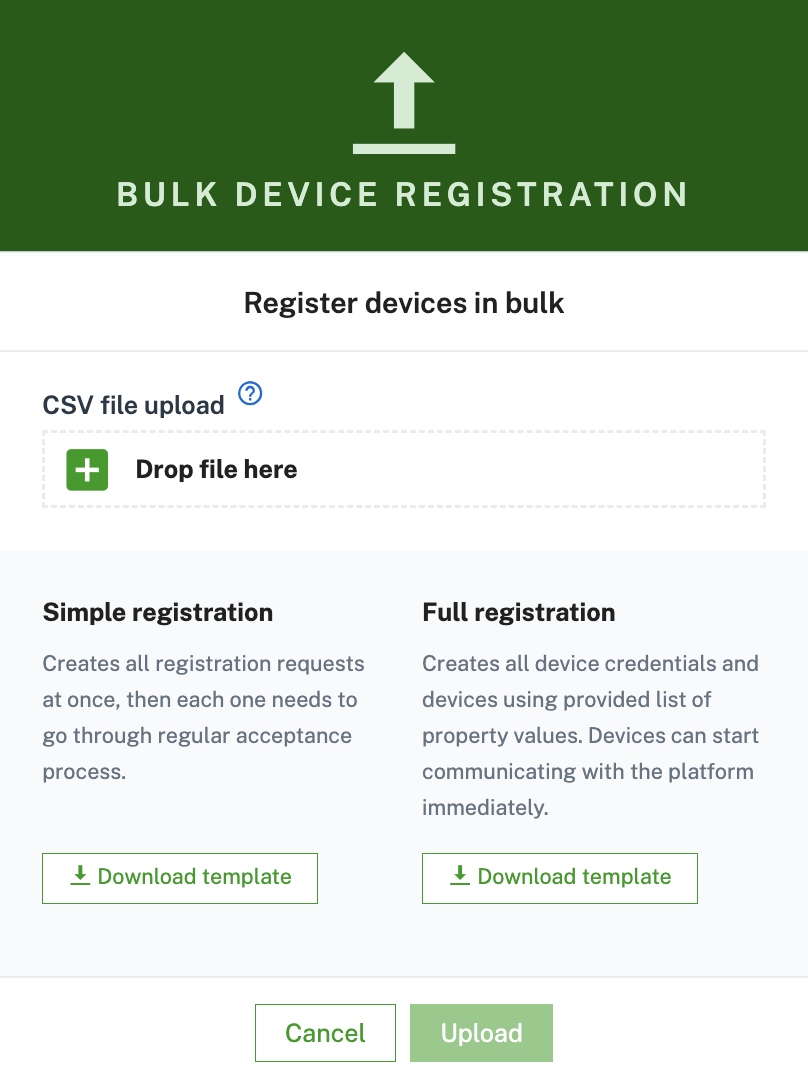

Easily integrate your devices and assets to start collecting data

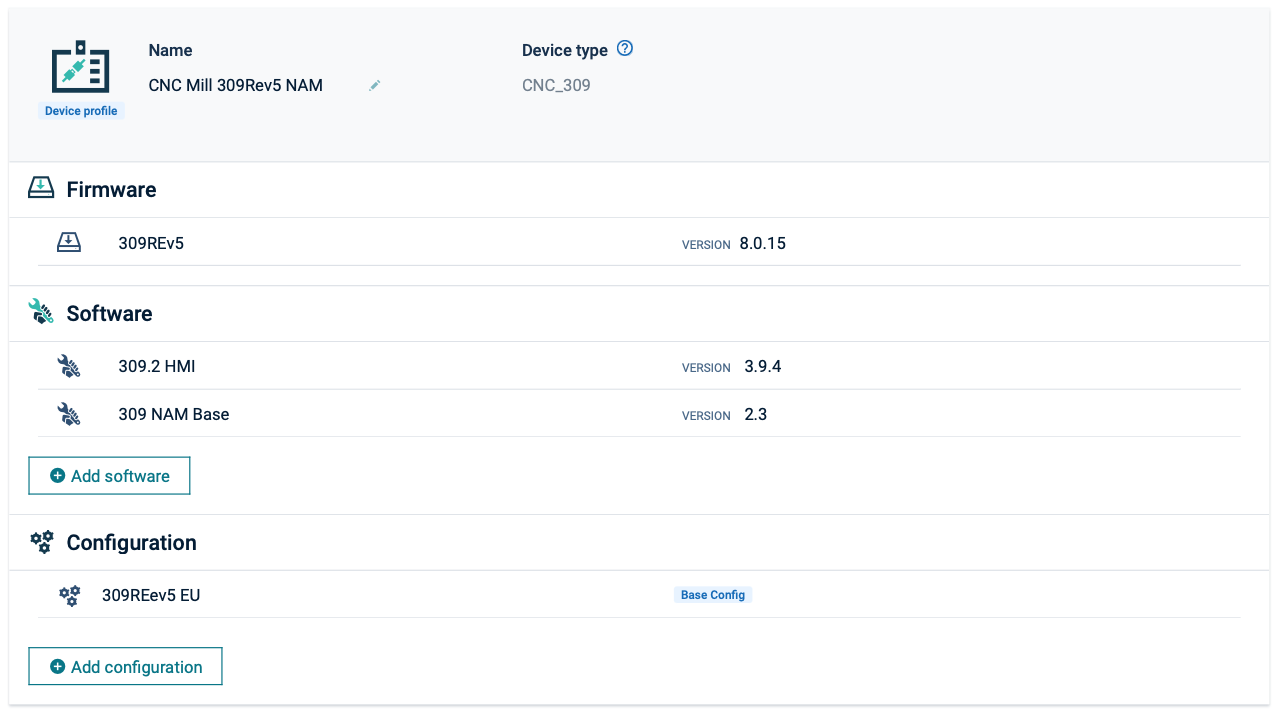

Make software and firmware updates OTA

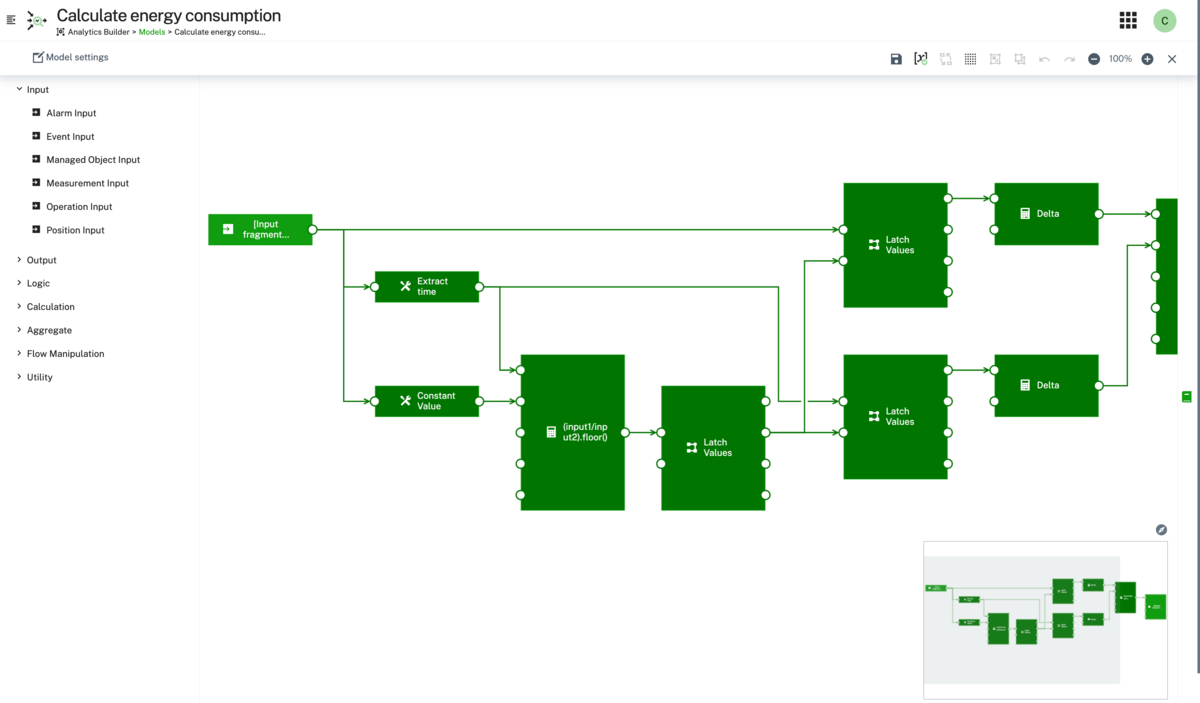

Trigger automated actions and responses with Streaming Analytics

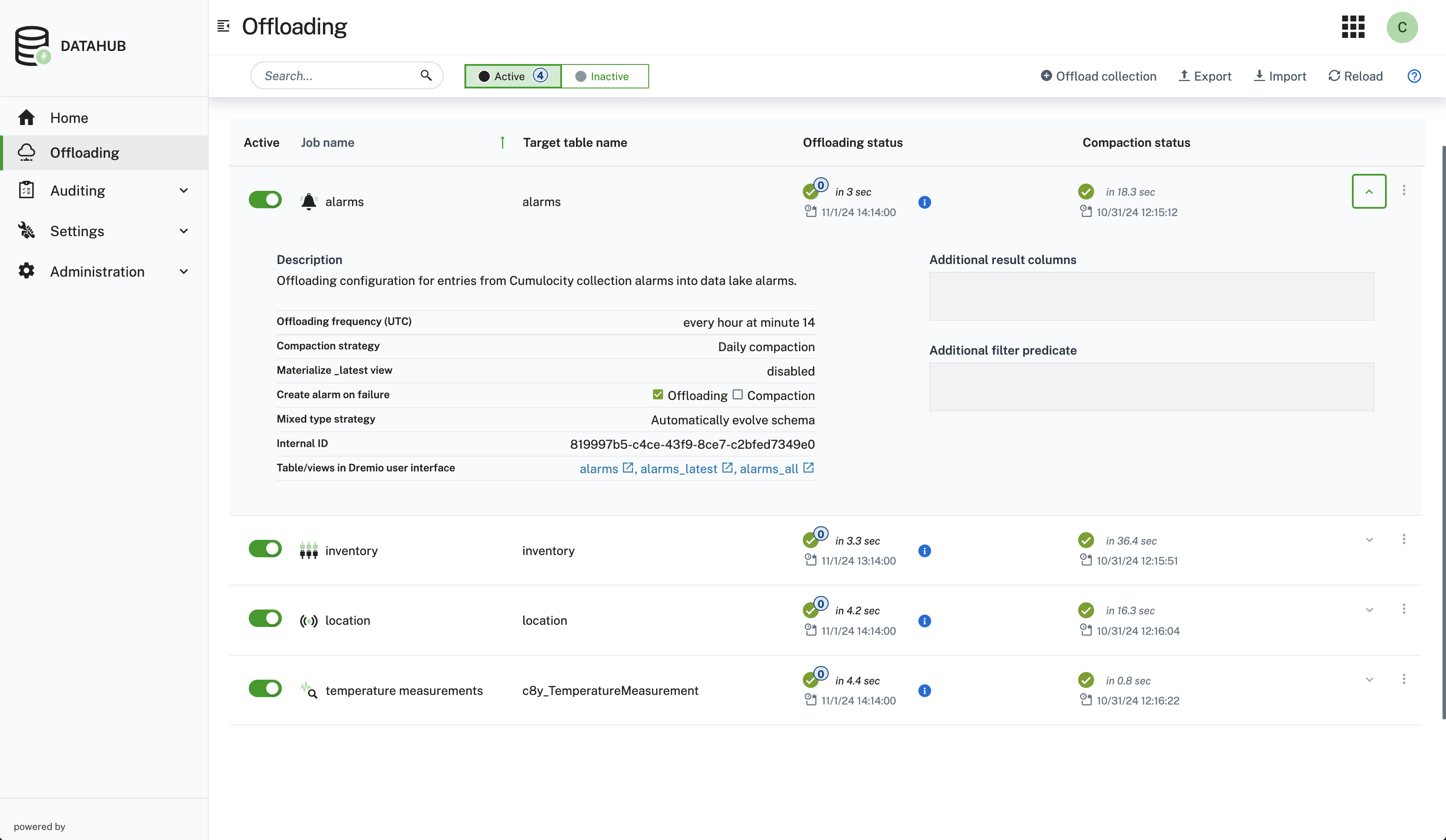

Make data available for downstream analytics

Improve Health and Safety for your workforce