Predictive Maintenance

Maximize asset runtime with Cumulocity

We could see that we needed a scalable system that will be able to handle ever larger quantities of data, and we also knew that a partner with specific expertise in this field would be beneficial so we can work on Predictive Modeling and using the data in a way only a domain expert can.

Paul Johnson

Senior Manager, Digital Transformation

Edwards

Get ahead by shifting from preventative to predictive maintenance

The cost of asset downtime is increasing

The average cost of an hour of downtime has more than doubled over the past five years to over $250,000, making an optimized maintenance routine even more critical.Improve your energy efficiency

Even if it continues operating, poorly maintained equipment runs less efficiently, leading to higher operating costs, especially energy costs. An optimized maintenance schedule leads to a more energy efficient equipment.Predictive maintenance unlocks worker productivity

Companies that have implemented preventive maintenance and other labor-saving automation technologies have experienced a productivity gain among maintenance staff of up to 66 percent, allowing process efficiency gains of 20-30%.AI is changing the landscape of digital services

Integration of AI and IoT solutions allows operators to enhance asset reliability, optimize maintenance scheduling, reduce costs, and achieve sustainability goals.The numbers tell the story

$260,000

hourly cost of unplanned equipment downtime.

Source: Aberdeen Research

5-20%

reduction in production capacity caused by a suboptimal maintenance program.

Source: Deloitte

18-25%

reductions in maintenance costs by shifting to a predicitive maintenance model.

Source: IIoT World

Easily connect and collect data from your assets

—Stelios Trikoulis

Chief Commercial Officer

Kallipr

Turn raw data into actionable insight

Deploy pre-built analytics templates to match your specific equipment characteristics and customer needs. Integrate AI models seamlessly with Cumulocity and operationalize it on incoming IoT data from your connected devices. Utilize Streaming Analytics to effortlessly feed live IoT data into your model and let it generate actionable insights and drive impactful actions.

For more information, visit the Cumulocity documentation.

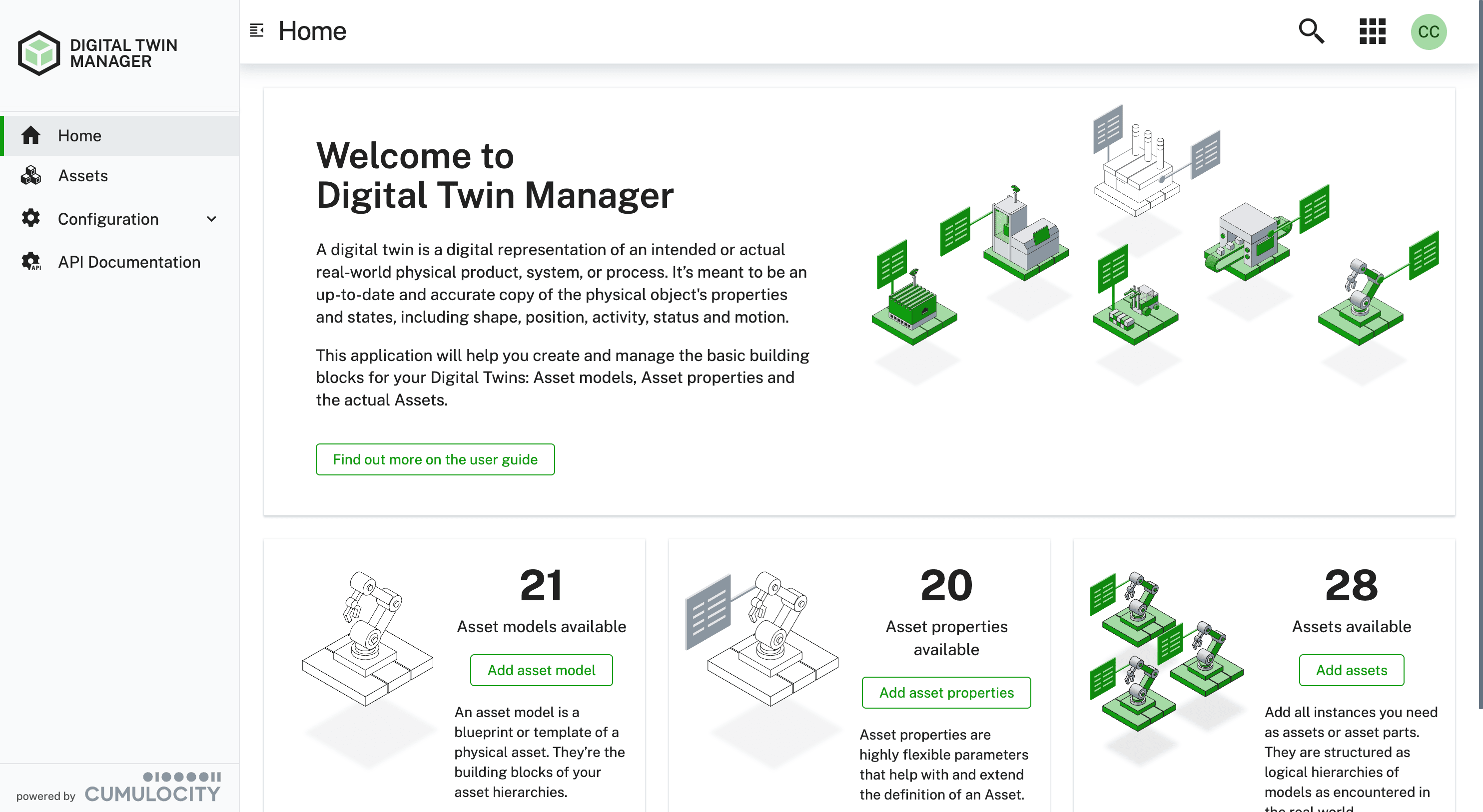

Build a digital representation of your physical assets

Make data available across the business

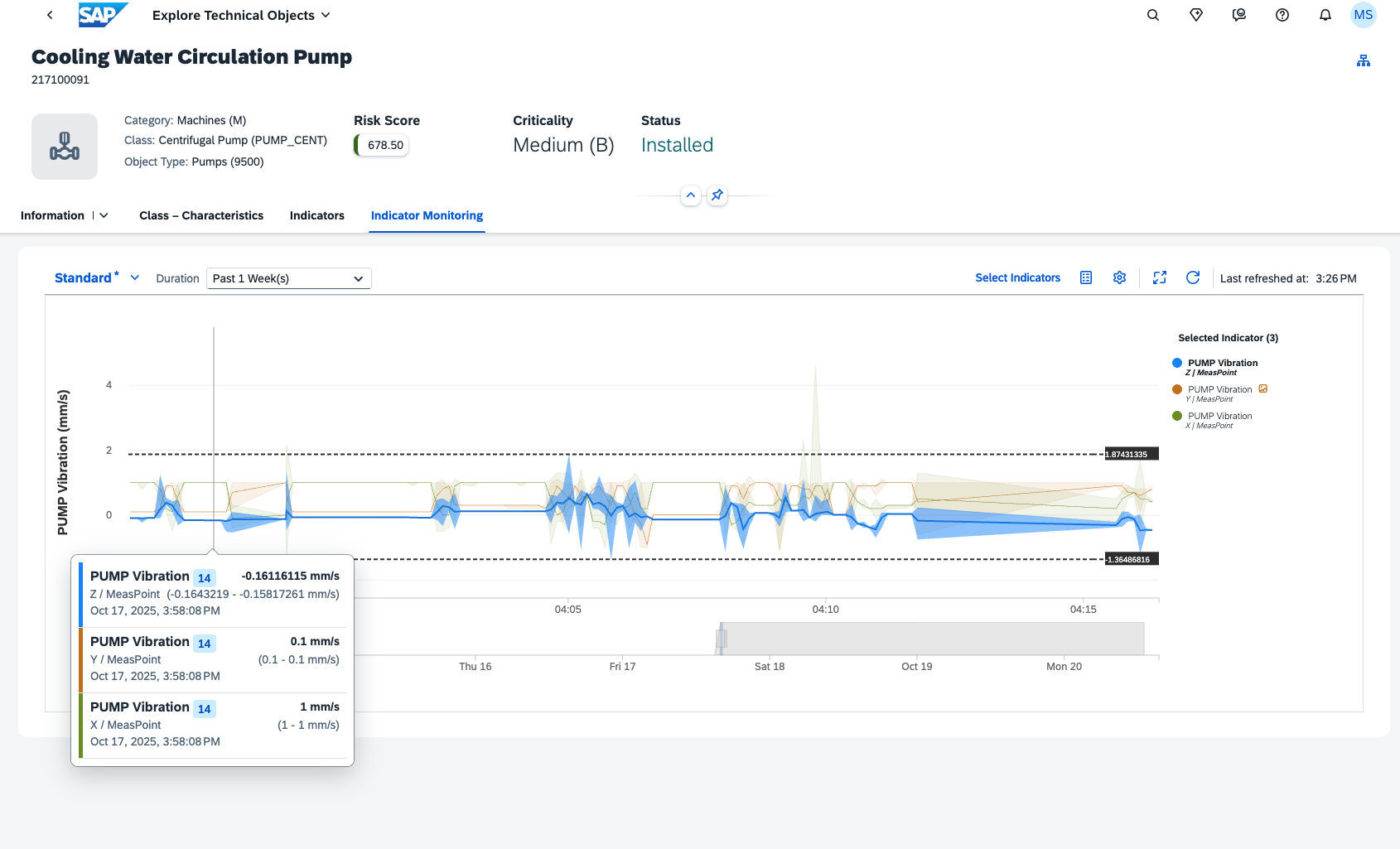

Cumulocity is embedded in SAP Asset Performance Management

As part of the partnership between Cumulocity and SAP, Cumulocity now powers SAP Asset Performance Management, allowing customers to implement predictive maintenance, anomaly detection, and closed-loop monitoring—driving measurable reductions in equipment downtime and maintenance costs.

Learn more about our partnership with SAP.

Frequently asked questions

Predictive maintenance is a system for scheduling repair work on an enterprise asset based on the actual condition of the machine rather than a set schedule or in response to specific failure. As assets have been fitted with more sensors that generate data, there has been exponential growth in the amount of historical data available on operating conditions; combining that with failure data is a core competency of an IoT platform.

Implementing predictive maintenance with involves a systematic process of data collection, analysis, and action. Manufacturers can follow these steps:

Connectivity and data collection

- Predictive maintenance depends on reliable asset data. Manufacturers must deploy IoT sensors on critical machinery to collect real-time data on operational parameters such as vibration, operating speeds, temperature, acoustic emissions, and motor current.

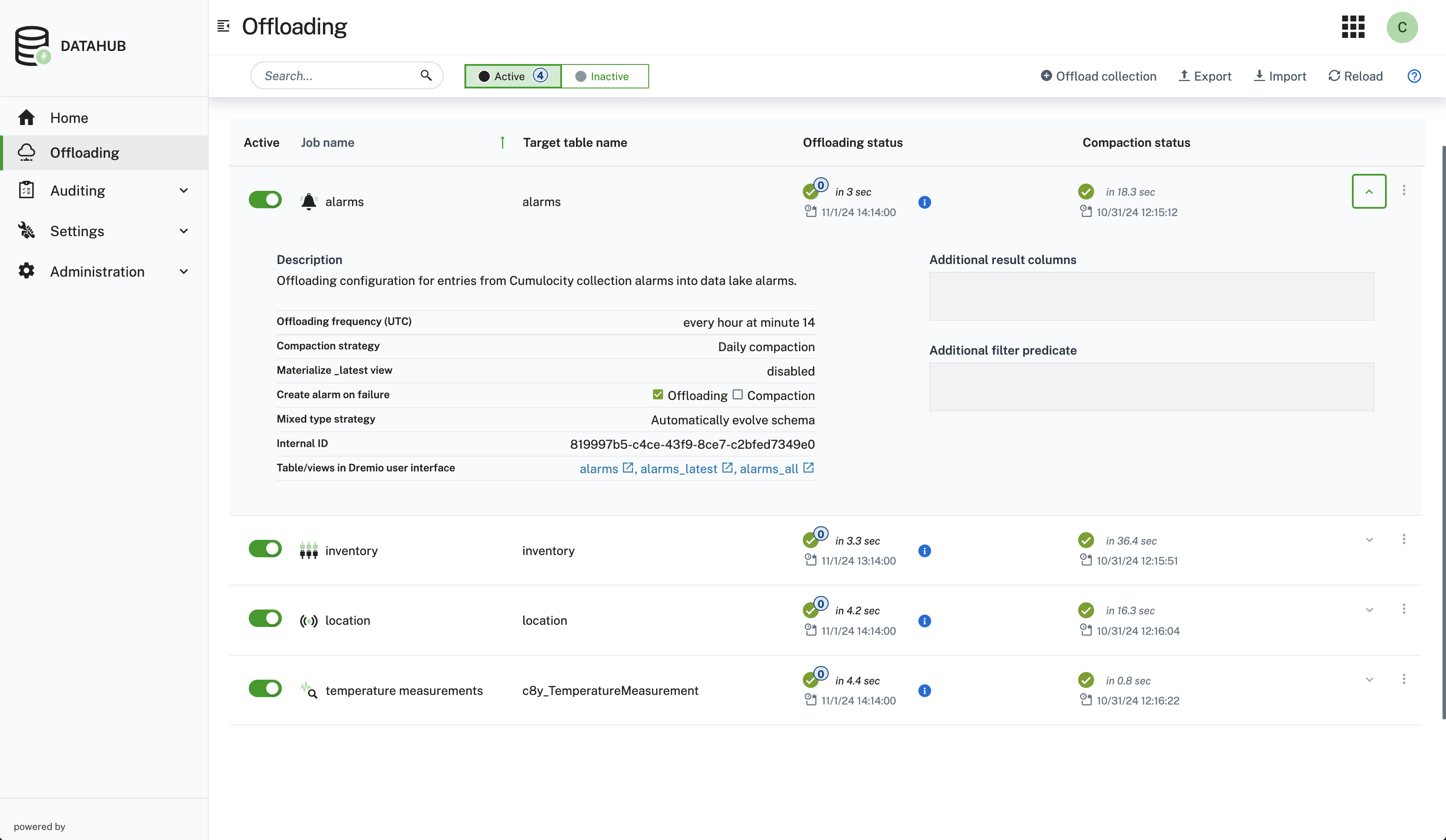

- Collecting and consolidating this data is one of the jobs of an IoT platform such as Cumulocity. The data is transmitted via the platform to a central cloud or edge computing system for storage and processing.

Data integration

- The sensor data must be integrated with other relevant data sources, such as historical maintenance records, operational data from the MES, and ERP data. The data then needs to be cleaned, normalized, and formatted for use by AI algorithms. An IoT platform that can ingest data from a variety of sources through prebuilt or bespoke APIs can facilitate this process.

AI Model Training and Deployment

- The trained AI models are then deployed back into the IoT platform to continuously monitor live data streams and provide real-time insights.

Actionable Intelligence Generation

- Alerting: The system generates alerts and notifications for maintenance teams when a potential failure is predicted.

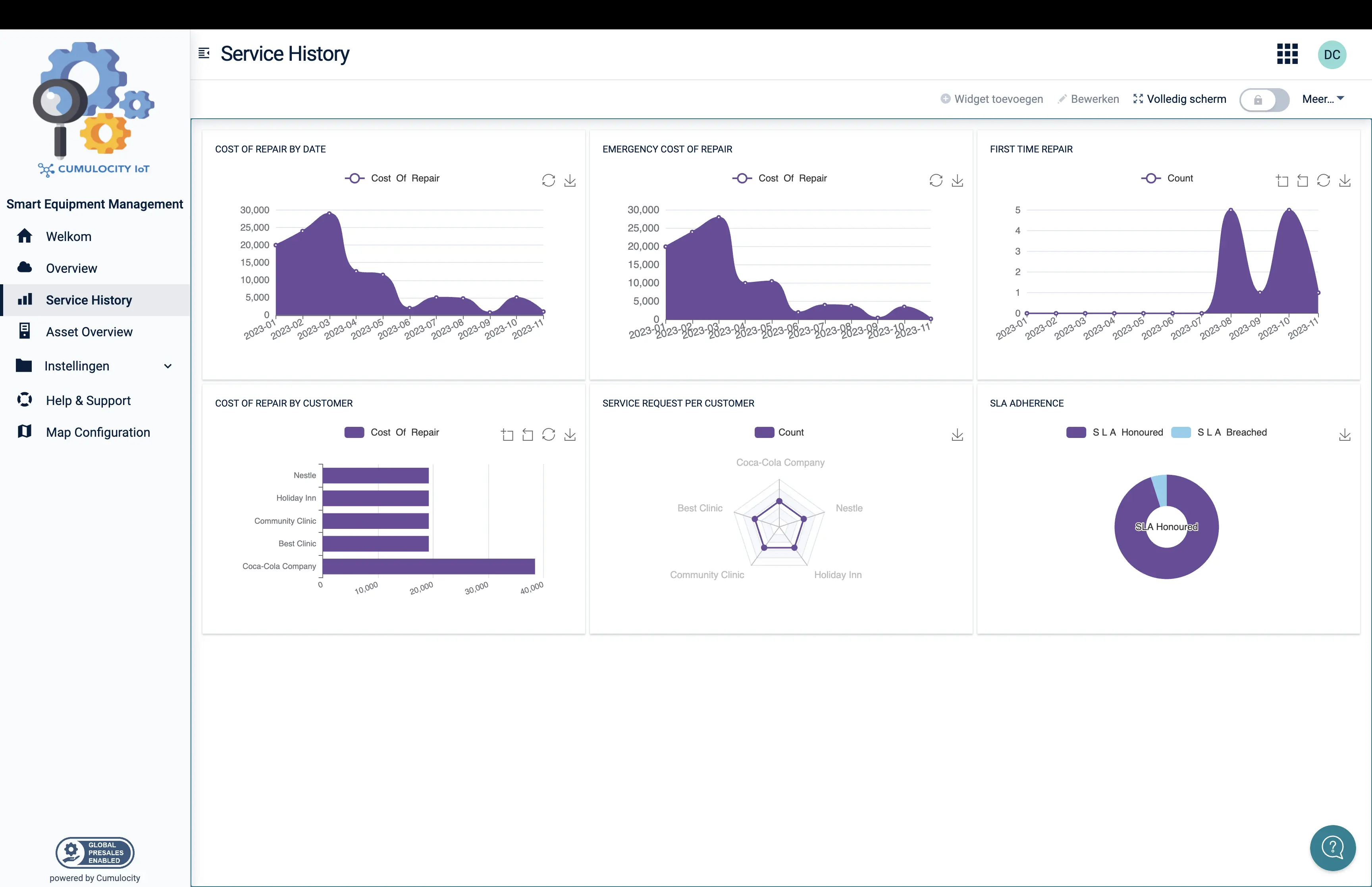

- Dashboards and Visualization: Intuitive dashboards display equipment health scores, remaining useful life estimates, and recommended actions, enabling timely and informed decision-making.

Continuous Improvement

- Feedback from operators and maintenance teams—such as confirmation of a predicted failure or identification of new failure modes—is used to continuously refine and retrain the AI models, improving the accuracy and effectiveness of the entire predictive maintenance program over time.